Clostridium Butyricum TO-A Discussion Paper

On this page

Skip the menu of subheadings on this page.Committee Paper for Discussion - ACNFP/162/13

Advisory Committee for Novel Foods and Processes

Application for Authorisation as a Novel Food Clostridium Butyricum TO-A

Application number RP1396

Issue

A dossier has been received under the novel food authorisation process (Regulation 2015/2283 under EU retained law) for Clostridium butyricum TO-A. A previous strain of C. butyricum was authorised in 2014 and this company is seeking use of the new strain in food supplements for a range of age groups.

The Committee are asked to advise whether the available data provides an adequate basis for a risk assessment, and if it is able to reach an opinion on whether the novel

food is safe for use and not nutritionally disadvantageous under the proposed uses.

Background

1. On the 29th December 2021, the FSA received the submission for Clostridium butyricum TO-A from TOA Biopharma Co. Ltd. This is a new strain of C.butyricum from the one approved as a novel food in 2014, following a UK safety assessment.

2. The novel food is Clostridium butyricum TO-A a white-grey powder that contains live C. butyricum TO-A at 1 x 109 cfu/g. It is manufactured by fermentation. The applicant proposes to use the novel food as an ingredient in food supplements.

3. The full technical application dossier is attached as Annex A, attached as Annex B is the draft opinion from March 2013 for Clostridium butyricum CBM588 from the ACNFP under the previous authorisation regime 258/97 EC.

footnote A folder of the literature referenced within the application is attached as Annex C. The key appendices to this document are attached as Annexes D to Y, which contain confidential and commercially sensitive information. The following pages contain a summary of the dossier submitted by the applicant.

This Application

Identification

4. The novel food is Clostridium butyricum TO-A a white-grey powder that contains live C. butyricum TO-A at 1 x 109 cfu/g. It is manufactured by fermentation. C. butyricum TO-A is a spore-former, strictly anaerobic, and belongs to the Gram-positive Clostridium genus. C. butyricum TO-A is formulated with a carrier (potato starch (CAS 9005-25-8)) added at 80-90% to achieve the intended level of C. butyricum TO-A at 1 x 109 cfu/g. This is a different strain produced by a new applicant that differs from the version approved as a novel food in 2014.

5. When grown anaerobically at 37ºC in iron sulfite agar (pour-plate technique) for 24 hours, C. butyricum TO-A circular black colonies appear. Gram-staining reveals straight or slightly curved rod-shaped cells and oval spores (Annex D). C. butyricum TO-A was sequenced (Annex E) and subsequent unique taxonomical identification was performed, based on the 16S rRNA gene and the whole genome sequence (alignment-free distance estimation, average nucleotide identity, whole genome alignment and phylogenetic tree) (Annex F).

6. The applicant concluded that the test strain in Annex F is Clostridium butyricum. The 16S rRNA gene analysis and the alignment-free distance estimation indicated the closes type strain was Clostridium butyricum VPI3266 (DSM 10702). The highest ANI (average nucleotide identity) value of 99.9956% was obtained between the test strain and C. butyricum KNU-L09.

Likewise, the core gene alignment grouped the test strain together with Clostridium butyricum KNU-L09. The currently authorised strain is C. butyricum strain (CBM 588). No data has been provided on how similar C.butyricum TO-A is to CBM 588.

7. As highlighted in the previous ACNFP opinion on the novel food, C. butyricum was considered by EFSA’s BIOHAZ Panel in its 2011 update to the QPS list. EFSA concluded that “the safety of Clostridium butyricum is a strain-related property, therefore Clostridium butyricum should not be recommended for the QPS list.” This conclusion was based on the observation that a minority of strains contain a gene coding for botulinum neurotoxin type E and there is only limited knowledge of human and animal exposure to this species. As QPS does not apply, the microorganism requires a full novel food assessment.

8. The applicant has provided in Table I.1.1 (Annex A 1.1) antimicrobial susceptibility testing of C. butyricum TO-A, which shows phenotypic resistance against kanamycin and streptomycin, however no risk of horizontal transfer is expected as C. butyricum TO-A is anaerobic, and anaerobic bacteria are known to be intrinsically resistant to aminoglycosides. Bioinformatic screening of C. butyricum resulted in the detection of 3 potential antimicrobial resistance genes, it was concluded the genes did not contain resistance-conferring mutations in the chromosome or plasmid of C. butyricum TO-A. The applicant has used the AMR phenotypic and bioinformatic results to conclude C. butyricum TO-A does not harbour AMR genes (Annex F).

Production Process

9. C. butyricum TO-A was originally isolated from the gut contents of healthy humans and it is deposited in the Japanese National Institute of Technology and Evaluation Patent, under the Budapest Treaty on the International Recognition of the Deposit of Microorganisms under the number FERM BP10866 (Annex Z). The strain deposit certificate is valid for 30 years.

10. C. butyricum TO-A is produced by anaerobic fermentation using an appropriate culture medium. The cells are harvested by centrifugation and mixed with an excipient to achieve the desired concentration of C. butyricum TO-A. Subsequently, the final product is packed. A simple flowchart of the manufacture of C. butyricum TO-A is provided in Figure I.2.1 (Annex A 1.0). The manufacturer, TOA Biopharma Co. Ltd., is compliant with GMP standards (Annex G).

11. A detailed confidential description of the manufacturing process and quality control steps is provided in Annex H. Details of the ingredients used in the manufacturing process are provided in Annexes I, J and K.

Composition and Specification

12. The applicant has reported analytical data for a number of independent batches of C. butyricum TO-A. The data indicates that the manufacturing process results in a consistent final ingredient that meets the proposed specifications for the novel ingredient.

13. The applicant reported data of five batches of Clostridium butyricum TO-A in Table I.3.1.1 (Annex L, Annex M). Purity data is provided in Annex N. Reference to analytical methods, limits of detections and limits of quantification are included in the Annexes. Full description of the analytical methods is provided in Annex O. Accreditations of the laboratories of analysis are provided in Annex P.

Table I.3.1.1 Batch variation of 5 lots of C. butyricum TO-A.

|

|

A2021.3. 11 |

B2021.3. 11 |

C2021.3. 11 |

D2021.3. 11 |

E2021.3. 11 |

|

Sulfitereducing bacteria (Clostridium) counts (cfu/g) |

5.2 x 109 |

4.0 x 109 |

3.9 x 109 |

4.9 x 109 |

5.3 x 109 |

|

Moisture & volatile matters (%) |

1.81 |

1.64 |

1.59 |

2.09 |

1.52 |

|

Crude protein (%) |

0.60 |

0.57 |

0.63 |

0.72 |

0.63 |

|

Crude fat (%) |

<0.20 |

<0.20 |

<0.20 |

<0.20 |

<0.20 |

|

Fibre (%) |

1.91 |

1.22 |

1.80 |

0.96 |

1.51 |

|

Ash (%) |

0.43 |

0.48 |

0.46 |

0.42 |

0.34 |

|

Sodium (as Na) (%) |

0.078 |

0.076 |

0.076 |

0.076 |

0.077 |

|

Carbohydrates (%) |

95.25 |

96.09 |

95.52 |

95.81 |

96.00 |

|

Fructose (%) |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

|

Glucose (%) |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

|

Saccharose (%) |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

|

Maltose (%) |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

|

Lactose monohydrate (%) |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

|

Metabolizable energy (Kcal/100g) |

387 |

389 |

388 |

388 |

390 |

|

Metabolizable energy (KJ/100g) |

1645 |

1653 |

1649 |

1649 |

1655 |

|

Sum of saturated fatty acids (g/100g |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

|

Sum of monounsaturat ed fatty acids (g/100g |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

|

Sum of polyunsaturate d fatty acids (g/100g |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

|

Sum of omega3 fatty acids (g/100g) |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

|

Sum of omega6 fatty acids (g/100g) |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

Note: Reference to methods of analysis and limits of detection are provided in Annexes L and M. Description of analytical methods is provided in Annex O.

Table I.3.1.2. Purity of 5 lots of C. butyricum TO-A.

|

|

A2021.3 .11 |

B2021.3 .11 |

C2021.3 .11 |

D2021.3 .11 |

E2021.3 .11 |

|

APC (cfu/g) |

<4 x 101 |

<4 x 101 |

<10 |

<4 x 101 |

<4 x 101 |

|

Yeasts (cfu/g) |

<1 x 102 |

<1 x 102 |

<1 x 102 |

<1 x 102 |

<1 x 102 |

|

Moulds (cfu/g) |

<1 x 102 |

<1 x 102 |

<1 x 102 |

<1 x 102 |

<1 x 102 |

|

Salmonella spp. (cfu/25g) |

ND |

ND |

ND |

ND |

ND |

|

Total coliforms (cfu/g) |

<10 |

<10 |

<10 |

<10 |

<10 |

|

E. coli (cfu/g) |

<10 |

<10 |

<10 |

<10 |

<10 |

|

Cadmium (mg/kg) |

<0.20 |

<0.20 |

<0.20 |

<0.20 |

<0.20 |

|

Lead (mg/kg) |

<2.50 |

<2.50 |

<2.50 |

<2.50 |

<2.50 |

|

Arsenic (mg/kg) |

<2 |

<2 |

<2 |

<2 |

<2 |

|

Mercury (mg/kg) |

<0.02 |

<0.02 |

<0.02 |

<0.02 |

<0.02 |

|

Aflatoxin B1 (µg/kg) |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

|

Aflatoxin B2 (µg/kg) |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

|

Aflatoxin G1 (µg/kg) |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

|

Aflatoxin G2 (µg/kg) |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

|

Ochratoxin A (µg/kg) |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

<0.50 |

|

Deoxynivalenol/Vo mitoxin (µg/kg) |

<40 |

<40 |

<40 |

<40 |

<40 |

|

Zearalenone (µg/kg) |

<10 |

<10 |

<10 |

<10 |

<10 |

|

Fumonisin B1 (µg/kg) |

<20 |

<20 |

<20 |

<20 |

<20 |

|

Fumonisin B2 (µg/kg) |

<20 |

<20 |

<20 |

<20 |

<20 |

|

T2-Toxin (µg/kg) |

<10 |

<10 |

<10 |

<10 |

<10 |

|

HT2-Toxin (µg/kg) |

<10 |

<10 |

<10 |

<10 |

<10 |

|

Pesticides (mg/kg) |

<0.005* |

<0.005* |

<0.005* |

<0.005* |

<0.005* |

|

Dioxins (PCDD/F) + dl PCBs, upper bound, TEQ-WHO (ng/kg)† |

0.24 |

0.24 |

0.25 |

0.24 |

0.24 |

|

Sum of ndl-PCBs (upper bound, ICES-6 (ng/kg)† |

3.30 |

1.65 |

3.30 |

3.30 |

3.30 |

Methods of analysis and limits of detection are provided in Annexes N. *Result for a large number of pesticides. In case of Diclorvos, the analytical results is < 0.01; for HCB, HCH, lindane the analytical result is < 0.001. †For results below the limit of quantification (LOQ), the LOQ is used to calculate. APC: Aerobic plate count; ND: not detected; PCDD: Polychlorinated dibenzo-p-dioxins; PCDF: polychlorinated dibenzofurans; dl PCBs: Dioxin-like polychlorinated biphenyls; ndl PCBs: Non-dioxin-like polychlorinated biphenyls; WHO-TEQ: World Health Organisation Toxic Equivalency; ICES: International Council for the Exploration of the Sea.

14. The applicant has reported the heavy metal content in five batches of the novel ingredient (see Table I.3.1.2). These results are below the EU permitted levels of food supplements: cadmium < 1.0 mg/kg; lead < 3.0 mg/kg; mercury < 0.1 mg/kg

15. The applicant has reported results for the microbial content in five batches of the novel ingredient (Annex N). The results confirm that aerobic plate count, and yeast and moulds, were below the specification limits of ≤ 10 cfu/g and ≤ 1 x 102 cfu/g respectively. E. coli was not detected in ≤ 10 cfu/g in 1g and Salmonella was not detected in 25g.

16. Due to the botanic nature of the carrier (Annex I), pesticides, dioxins and PCBs results have also been reported. Silicon (Si) atom results have also been reported for the detection of potential silicon-based residues of antifoaming agent used in the manufacture of C. butyricum TO-A (Annex J).

17. The novel food C. butyricum TO-A is a white-grey powder that consists of 8090% of potato starch (CAS 9005- 25-8), used as a carrier, and 10-20% of C. butyricum TO-A (1 x 109 cfu/g). The content of each ingredient is adjusted within the ranges indicated so that the count of C. butyricum TO-A is 1 x 109 cfu/g. Specifications and safety data sheet of potato starch are provided in Annex I.

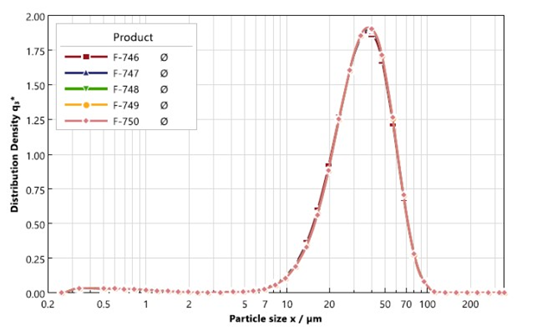

18. The applicant has presented results for the particle size and density of five batches C. butyricum TO-A. The particle size ranges from 16.02 – 16.63 µm (x10) to 84.16 – 84.85 µm (x99) (Table I.3.2.1). The density distribution curves q3lg(x) of all five samples indicate monomodal distribution (Figure I.3.2.1) (Annex Q). Results show samples contain both elongated as well as round particles, but overall the examined five batches of C.butyricum TO-A are homogenous in particle-size and shape.

Table I.3.2.1.Particle size and density of C. butyricum TO-A.

|

BatchNo. |

IFFcod e |

x101 |

x502 |

x903 |

x994 |

xh5 |

< 1 µm |

< 10 µm |

< 50 µm |

< 100 µm |

|

|

|

µm |

µm |

µm |

µm |

µm |

% |

% |

% |

% |

|

A2021.3. 11 |

F- 746 |

16.0 2 |

33.8 5 |

59.1 8 |

84.1 6 |

39.8 5 |

1.8 2 |

3.7 1 |

80.4 6 |

99.8 9 |

|

B2021.3. 11 |

F- 747 |

16.2 7 |

34.2 0 |

59.4 9 |

84.5 5 |

39.8 5 |

1.7 8 |

3.5 4 |

79.9 7 |

99.8 8 |

|

C2021.3. 11 |

F- 748 |

16.4 8 |

34.3 6 |

59.6 2 |

84.8 5 |

39.8 5 |

1.7 3 |

3.4 3 |

79.7 9 |

99.8 7 |

|

D2021.3. 11 |

F- 749 |

16.5 4 |

34.3 3 |

59.5 1 |

84.5 5 |

39.8 5 |

1,7 2 |

3.3 7 |

79.9 0 |

99.8 8 |

|

E2021.3. 11 |

F- 750 |

16.6 3 |

34.4 0 |

59.6 0 |

84.6 6 |

39.8 5 |

1.7 0 |

3.3 1 |

79.7 7 |

99.8 8 |

1 x10: The portion of particles with diameters smaller than this value is 10 %.

2 x50: The mean particle size. The portions of particles with diameters smaller and larger this value are both 50 %.

3 x90: The portion of particles with diameters smaller than this value is 90 %.

4 x99: The portion of particles with diameters smaller than this value is 99 %.

5 xh: The particle size which reflects the highest distribution density.

Figure I.3.2.1

Stability

19. Five independent batches of the companies C. butyricum TO-A were analysed in regard to its stability. The recommended storage conditions of C. butyricum TO-A are < 25ºC in a dry place ( 60% RH). The appearance, water content and amount of C. butyricum TO-A were analysed over time at 25 ºC (Annex R for time 0, Annex S for 1-month data, Annex T for 4-month data).

20. Data concerning the physicochemical properties, biochemical properties and microbiological properties were reported. The applicant states no significant changes were observed and therefore the novel food is considered stable for 4 months shelf life under normal storage conditions.

Specifications

21. The specification parameters for the novel food were assessed using internationally recognised methods or are otherwise determined using internally developed and validated methods (Table I.4.1).

Table I.4.1. C. butyricum TO-A specifications.

|

Parameter |

Specification |

Analytical method |

|

C. butyricum TO-A |

1 x 109 |

ISO 15213 |

|

Moisture |

<10% |

Regulation (EC) 152/2009 |

|

Coliform bacteria |

<10 cfu/g |

ISO 4832 |

|

Appearance |

White/grayish powder |

- |

|

Odour |

Odourless |

- |

History Of Use

22. Another strain of C. butyricum (C. butyricum MIYAIRI 588®) was authorised as a novel food for use in food supplements since 2014 by Commission Implementing Decision 2014/907/EU.

23. The applicant states C. butyricum TO-A is an ingredient of Bio-Three, which has been sold as a probiotic indicated for diarrhoea and digestive system health in Taiwan and China for decades and in Japan for approximately 60 years and has also been licensed in Canada in Probiotic-3 since 2009 (Annex U). To note the novel foods assessment in the UK does not consider the efficacy of the novel food or whether it has probiotic properties if these do not relate to the safety of the novel ingredient.

Proposed Use and Intake

24. The applicant states that the novel food is intended to be used by healthy children and healthy adults in food supplements. It is not intended to replace another food and the maximum proposed use levels are; Infants (3- <12 months) and toddlers: 1 x 108 cfu/day, Other children: 3 x 108 cfu/day, Adolescents: 6 x 108 cfu/day and Adults: 1 x 109 cfu/day.

25. The applicant states at the proposed use levels, the estimated intake of C. butyricum TO-A will be between 8.4 x 106 cfu/kg body weight/day (toddlers) and 1.49 x 107 cfu/kg body weight/day (infants 3-<6 months).

26. The novel food is not novel in the gut and the applicant states that other strains of C. butyricum such as MIYAIRI 588® are already available. The applicant expects consumers to substitute C. butyricum MIYAIRI 588® with C. butyricum TO-A or will continue consuming C. butyricum MIYAIRI 588® but will not be co-consuming both food supplements.

27. The applicant does not expect exposure to undesirable substances from the consumption of food supplements containing C. butyricum TO-A. However, Silicon was analysed in C. butyricum TO-A for the estimation of potential silicon-based residues of antifoaming agent used in the manufacture of the product.

28. Polydimethylsiloxane (PDMS, a silicon-based defoamer) is used as a processing aid in C. butyricum TO-A production. The maximum amount of PDMS in C. butyricum TO-A, if present at all, is estimated to be 0.005%. Considering the highest estimated intake of 14.93 mg C. butyricum TO-A/kg bw/day by infants (3-<6 months), the applicant states the potential maximum intake of PDMS from C. butyricum TO-A would be 0.00075 mg/kg bw/day. This value is below the acceptable daily intake (ADI) of 17 mg/kg bw/day established by EFSA (EFSA 2020), and therefore, the applicant reports the potential unavoidable presence of the processing aid PDMS it is not considered a safety concern.

Absorption, Distribution, Metabolism, Excretion (ADME)

29. The applicant reports no ADME studies are considered necessary for C. butyricum TO-A, as live microorganisms pass through the gut and are not absorbed as such. The novel food does not produce toxic substances that could be of concern and no evidence of production of compounds or molecules of relevance requiring toxicokinetic assessment have been found. In addition, adverse events were not reported in the review of the literature (Annex V) and toxicological studies.

Nutritional Information

30. The applicant reports the nutritional composition of five batches of C. butyricum TO-A in Table I.8.1 (Annex L). The applicant reiterates that C. butyricum TOA is not intended to replace another food and at the proposed dose is not nutritionally disadvantageous.

Toxicological Information

31. The applicant reports that C. butyricum TO-A has been characterized following EFSA Guidance on the characterisation of microorganisms used as feed additives or as production organisms (EFSA, 2018) and the statement on the requirement for WGS analysis (EFSA, 2021). The applicant concluded that C. butyricum TO-A does not produce toxic substances and is of no safety concern., (Annex F).

32. The applicant reports that results from a bacterial reverse mutation assay (OECD TG 471) show that the test item BIO-THREE® presented no mutagenic activity which can be extrapolated to C. butyricum TO-A (Annex W).

33. The applicant reports results from an in vitro mammalian cell micronucleus test on TK6 lymphoblastoid human cells showing the test item BIO-THREE® presented no genotoxic activity with a short-term treatment in absence and in presence of metabolic activation, and with a continuous treatment which can be extrapolated to C. butyricum TO-A (Annex X).

34. The applicant has provided a literature review (Annex V), with studies that support the non-genotoxic potential of C. butyricum TO-A.

35. The applicant reports the result from a 13-week oral dose safety study in rats (Annex Y) which was performed to evaluate the safety of BIO-THREE®. The results of the study reported a NOAEL of 3000mg/kg/day (9 x 108 cgu/kg/day) for C. butyricum TO-A and the other test articles for male and females.

36. The applicant states at the intended use levels of C. butyricum TO-A, the margin of exposures ranges from 60.3 (infants 3-<6 months) to 107.1 (toddlers) (Section 1.6.2 in Annex A 1.6).

37. In addition, the applicant has provided a literature review to demonstrate the safety of oral intakes of Clostridium butyricum TO-A or other non-pathogenic C. butyricum strains. No evidence of subchronic toxicity of non-pathogenic C. butyricum was found. The results and protocol of the literature search are provided in Annex V.

Allergenicity

38. The applicant states that C.butyricum is unlikely to elicit an allergic reaction as the protein content of C. butyricum TO-A is low (0.63%) (Annex L) and no allergic reactions have been reported in literature (Section 1.5 in Annex A 1.5).

Committee Action Required

- The Committee is asked whether the available data provide a satisfactory basis for evaluating the safety of this novel food ingredient.

- If so the Committee is asked whether it is content to recommend approval of this novel food as an ingredient in food supplements. If not, the Committee is asked to indicate what additional data would be required.

Secretariat

September 2023

Annexes

Annex A – Clostridium butyricum TO-A Novel Food Dossier (RP1396)

Annex B- Draft opinion for C. Butyricum (CBM 588) Annex C to Y – Attachments referenced within this document.